- 225

- 7 816 320

Topper Machine LLC

United States

Приєднався 1 гру 2020

Topper Machine LLC is a Manual Only, Machining, Welding, and Fabricating job shop located in Spooner, WI. I am Josh Topper, Owner of Topper Machine LLC. I started out in machining in High School. I worked in a punch press shop and learned a lot about Tool and Die work. I really enjoyed that work, but I had to move on. I went to an OEM and worked my way to lead machinist. I helped streamline their production with my knowledge of tooling. After that, I opened my own shop in 2012.

If you want to see cool machines and me running them, you are in the right place. I work in many fields and perform many out of shop services as well. My channel will focus on our shop services and equipment, along with some of these out of house activities and interests.

Machine Shop videos every Saturday morning at 6:00AM CST. Other content will be Wednesday morning, 6:00AM CST as available.

Please Like, Subscribe and enjoy!

Please check out my website:

toppermachine.com

If you want to see cool machines and me running them, you are in the right place. I work in many fields and perform many out of shop services as well. My channel will focus on our shop services and equipment, along with some of these out of house activities and interests.

Machine Shop videos every Saturday morning at 6:00AM CST. Other content will be Wednesday morning, 6:00AM CST as available.

Please Like, Subscribe and enjoy!

Please check out my website:

toppermachine.com

Repairing A Badly Worn, Obsolete Part for a Hay Baler - Manual Machine Shop

This job is something that I am seeing more and more of. Customer brings a part and tells me that it is almost $3000.00 to replace, and no used ones exist. Can you fix it?

Absolutely, I can fix it. This job saved my customer a ton of money and a long lead time. He said the part would be about 2 months out from the dealer. He told me the New Holland equipment is being obsoleted in short order and parts are almost nonexistent. He can still source this, but not easily.

If you are interested in trying out Anchorlube, here is a link to their amazon store.

www.amazon.com/Anchorlube-All-Purpose-Metalworking-Compound-8oz/dp/B098MPVTPM/ref=sr_1_1?crid=194QBR3NDN9LO&keywords=anchorlube&qid=1691522441&sprefix=anchorlub%2Caps%2C265&sr=8-1

Topper Machine LLC is an entirely manual machine shop located in Spooner, WI. Our videos will highlight some of our shop work.

Thank you for watching!

Please Like, Subscribe, & Share.

toppermachine.com

Join this channel to get access to perks:

ua-cam.com/channels/hbIWit7NUfDYxKEnMDkaag.htmljoin

For Official Topper Machine LLC merchandise, check out our Teespring shop.

toppermachinellc.creator-spring.com/

Support our channel, Paypal donations are greatly appreciated.

www.paypal.com/donate?hosted_button_id=NCH6C5MSTJJHJ

#machineshop #machinistlife #manualmachinist

Absolutely, I can fix it. This job saved my customer a ton of money and a long lead time. He said the part would be about 2 months out from the dealer. He told me the New Holland equipment is being obsoleted in short order and parts are almost nonexistent. He can still source this, but not easily.

If you are interested in trying out Anchorlube, here is a link to their amazon store.

www.amazon.com/Anchorlube-All-Purpose-Metalworking-Compound-8oz/dp/B098MPVTPM/ref=sr_1_1?crid=194QBR3NDN9LO&keywords=anchorlube&qid=1691522441&sprefix=anchorlub%2Caps%2C265&sr=8-1

Topper Machine LLC is an entirely manual machine shop located in Spooner, WI. Our videos will highlight some of our shop work.

Thank you for watching!

Please Like, Subscribe, & Share.

toppermachine.com

Join this channel to get access to perks:

ua-cam.com/channels/hbIWit7NUfDYxKEnMDkaag.htmljoin

For Official Topper Machine LLC merchandise, check out our Teespring shop.

toppermachinellc.creator-spring.com/

Support our channel, Paypal donations are greatly appreciated.

www.paypal.com/donate?hosted_button_id=NCH6C5MSTJJHJ

#machineshop #machinistlife #manualmachinist

Переглядів: 27 892

Відео

Why I Fixed This Hydraulic Trunnion The Way I Did - Trunnion Repair Follow-up

Переглядів 13 тис.День тому

Every job has its challenges and are great learning experiences. In the 25 years I have been doing jobs like this, I have seen many failures of attempted repairs. Hydraulic cylinders with trunnion mounts of this style are generally not a high pressure application, so sleaving is the absolute best option. Welding and turning down brings in its own potential problems, which I have had first hand ...

Hydraulic Cylinder Trunnion Mount Repair - Manual Machining

Переглядів 29 тис.День тому

Some repairs come in that are just awe inspiring to the amount of damage that was done. I was surprised this was let go this far. This Trunnion head for a hydraulic cylinder has been beat badly, and will be an easy fix. But, why repair something like this? To save the customer money. A new cylinder is around $3000.00, a repair and repack will be a fraction of that. Way more economical than thro...

What Is Next For The Bantam C35 Dragline Crane? Track Roller Follow-up. Viewer Questions Answered

Переглядів 12 тис.День тому

Saturday's video had a lot of great questions, and I will answer as many as I can in this video. From what repair is next to why Conner wears a mask. If you want to know more about the Wisconsin Youth Apprenticeship Program, check out their website. dwd.wisconsin.gov/apprenticeship/ Topper Machine LLC is an entirely manual machine shop located in Spooner, WI. Our videos will highlight some of o...

Working on More Repairs to the Bantam C35 Dragline Crane - Track Roller Removal and Disassembly

Переглядів 24 тис.14 днів тому

The Bantam C35 Dragline Crane I bought last year is getting a lot of work done to it. Most of this work is being done by my shop apprentice. Conner has learned a lot working with me in the shop and is doing a fantastic job on these projects. The repairs to the crane are mostly in the track assembly. Between the wear on everything and neglect, it is turning into quite a project. Once done, this ...

Minneapolis Crankshaft Follow-Up and Taper Turning on a Trailer Spindle

Переглядів 19 тис.14 днів тому

While I am unable to be there to repour the bearings on the Minneapolis, we did find it to be a 1/8 inch out of square. This was causing the angular travel of the connecting rod and the binding we saw. If you have any information of what actually happened to this engine while at Rollag, please let me know. Topper Machine LLC is an entirely manual machine shop located in Spooner, WI. Our videos ...

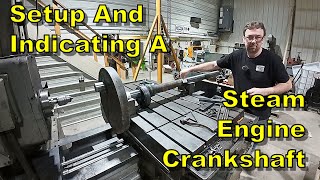

Minneapolis Steam Engine Crankshaft Troubleshooting - Horizontal Boring Mill Setup and Indicating

Переглядів 43 тис.21 день тому

My local threshing show was donated a 25 HP Minneapolis steam traction engine last year. The engine and boiler are in good shape, but we discovered a problem. The connecting rod was traveling at an angular motion. Something I have seen before, but not this bad. Supposedly this engine suffered a crankpin failure and was repaired. What we assumed would be the crank pin being out of alignment with...

Every Job Is A Learning Experience - This One Was No Exception - Manual Machining Long Parts

Переглядів 18 тис.21 день тому

Every job can teach you something. Some lessons are ones you should have thought about ahead of time. This video, I talk about what I learned doing these weld coupons, along with doing another job at the same time. Fun stuff, just another day in the shop. If you are interested in trying out Anchorlube, here is a link to their amazon store. www.amazon.com/Anchorlube-All-Purpose-Metalworking-Comp...

Machining Weld Test Coupons for the Local Technical College - Machining 8 Foot Long Bars of Steel

Переглядів 25 тис.28 днів тому

Some jobs are just taken to help out others. This job is for the local technical college weld program. We are machining the Weld Coupons for them to do their weld certifications on. I mill these ever couple months, and it has been easier and cheaper to mill 8 feet at a time. They can cut them to the lengths they want, so it's a win for both of us. Doing jobs like these are definitely not profit...

My Story of Running My Business in the Economically Depressed Region of Northern Wisconsin.

Переглядів 29 тис.Місяць тому

Northern Wisconsin is a beautiful place. It is my home and where I started my machine shop. But industry is disappearing, or not being allowed to locate here. For some reason they want to keep up depressed. This video is a follow-up to Saturday's video of the shop tour and closure of Worldwide Machining & Welding in Superior, WI. I talk about what I have gone through to survive and some of what...

Machine Shop Tour, Closing, and Complete Sale of Worldwide Machining & Welding in Superior Wisconsin

Переглядів 64 тис.Місяць тому

I have said this many times before that Northern Wisconsin is extremely depressed. I WAS NOT JOKING ABOUT THIS! Over the last 20 years, businesses have been closing or moving out of the area. People struggle to survive here; it is a total economic dead zone. The closure of Worldwide Machining & Welding, Inc. comes as a bit of a surprise, but given the region, it was almost expected. John Anders...

How could I have done this job differently? Plate Chiller Plate Milling Follow-up.

Переглядів 18 тис.Місяць тому

Now that I have done this job twice, once on the planer, and once on the HBM. I definitely had room for improvement. I also address the questions and suggestions in Saturday's video. Be sure to check out next Saturday's video of the Shop Tour and Closure of Worldwide Machining & Welding, Inc. You definitely don't want to miss this one. Topper Machine LLC is an entirely manual machine shop locat...

Milling Another Heat Exchanger Plate on the Horizontal Boring Mill - Manual Machining

Переглядів 45 тис.Місяць тому

A while back, I was brought a plate for a heat exchanger to mill down. The acid wash that was done on it had damaged the plate by pitting the surface. That plate was set up and milled on the Planer Mill. This time I do it on the Lucas HBM. Check out the other video to see the differences in operation and decide for yourself which way was better. Topper Machine LLC is an entirely manual machine ...

Setting Up a Face Mill - Finding the Odd Insert - Angle Plate Machining Follow-Up

Переглядів 22 тис.Місяць тому

On Saturdays video, I machined my big shop made angle plates. But, I had a small problem which I did not address. One insert was cutting deeper than the other 9. In this video, I show how to indicate and find the oddball insert and get the facemill tuned up and cutting like a dream. Topper Machine LLC is an entirely manual machine shop located in Spooner, WI. Our videos will highlight some of o...

Milling Shop Made Angle Plates on the Horizontal Boring Mill - Shop Built Tools

Переглядів 40 тис.Місяць тому

Perfection takes time. But 10 years was a little ridiculous. I made these for one job, and they worked. I planned on getting back to them, but now I have a job for them. So, it is time to finish them. The Lucas 441B-48 Horizontal Boring Mill makes quick work of these with the 8" Face Mill. Even though I had some difficulties with vibration early on, I found a solution to overcome and get the jo...

Replacing a Badly Worn Shaft and Saving My Customer a Pile of Money - Manual Machining & Welding

Переглядів 369 тис.Місяць тому

Replacing a Badly Worn Shaft and Saving My Customer a Pile of Money - Manual Machining & Welding

Machining a New Barrel Nut for a Hydraulic Cylinder - Manual Machining

Переглядів 54 тис.2 місяці тому

Machining a New Barrel Nut for a Hydraulic Cylinder - Manual Machining

Changes Made On The Robotic Welder Parts Job - Lessons Leaned Since The First Parts.

Переглядів 23 тис.2 місяці тому

Changes Made On The Robotic Welder Parts Job - Lessons Leaned Since The First Parts.

Machining Parts for a Robotic Welding Machine on the Horizontal Boring Mill - Manual Machining

Переглядів 38 тис.2 місяці тому

Machining Parts for a Robotic Welding Machine on the Horizontal Boring Mill - Manual Machining

Why I Adjust my Tool Height for Internal Chamfering on the Lathe - Machine Shop Tricks & Hacks

Переглядів 36 тис.2 місяці тому

Why I Adjust my Tool Height for Internal Chamfering on the Lathe - Machine Shop Tricks & Hacks

Making Custom Bushings for a Komatsu Wheel Loader - Heavy Equipment Repair Parts

Переглядів 82 тис.2 місяці тому

Making Custom Bushings for a Komatsu Wheel Loader - Heavy Equipment Repair Parts

Repairs to the Badly Worn Tracks on the Bantam C35 Dragline Crane

Переглядів 46 тис.2 місяці тому

Repairs to the Badly Worn Tracks on the Bantam C35 Dragline Crane

"Magic Chuck" Drill Chuck System Explained, & What Went Wrong In My Last Video

Переглядів 16 тис.2 місяці тому

"Magic Chuck" Drill Chuck System Explained, & What Went Wrong In My Last Video

Drilling & Countersinking AR500 Plate Steel. This Is Some Tough Stuff!!!

Переглядів 70 тис.3 місяці тому

Drilling & Countersinking AR500 Plate Steel. This Is Some Tough Stuff!!!

Making a Larger Table for the Radial Drill

Переглядів 32 тис.3 місяці тому

Making a Larger Table for the Radial Drill

Lion Manual Lathe, 2 Full Years of Ownership Review. The Good, Bad and Ugly

Переглядів 31 тис.3 місяці тому

Lion Manual Lathe, 2 Full Years of Ownership Review. The Good, Bad and Ugly

Is This Cheap Plasma Cutter Worth $200? Bestarc BTC500 on Amazon

Переглядів 23 тис.3 місяці тому

Is This Cheap Plasma Cutter Worth $200? Bestarc BTC500 on Amazon

Behind The Scenes, What It Takes To Make A Topper Machine LLC Video. Filming, Editing, & Uploading

Переглядів 8 тис.3 місяці тому

Behind The Scenes, What It Takes To Make A Topper Machine LLC Video. Filming, Editing, & Uploading

Single Point Threading, Using A Followrest. 24 Inches of 2"-4 1/2TPI Threads

Переглядів 52 тис.4 місяці тому

Single Point Threading, Using A Followrest. 24 Inches of 2"-4 1/2TPI Threads

Milling a Badly Pitted Plate for a Plate Chiller on the Metal Planer Mill

Переглядів 144 тис.4 місяці тому

Milling a Badly Pitted Plate for a Plate Chiller on the Metal Planer Mill

You gotta give yourself more credit.👍

One more thing that proves you and your wife are good people. As you said in the video, bees do alot of stuff for food production, other insects etc. Bees are important for the world and I thank you.

Hi Josh & it's is Randy and i like yours video is cool & Thanks Josh & Friends Randy

That was a high stress moment... averted.. Better to set up the press-shrink fit in the press with the press ready to press before heating the part while the stud is cooling off in dry ice. If the stud is even a tiny bit off axis even with a few thousands of clearance the stud will likely get stuck on the way down the hole. More often than not, the press I needed to avert a Oooops and not fun at ll re-do.. There is a tendency for metal to stick when they are close together, this is why clearance alone is not enough. Some means of mechanical aid (force) is often needed to over come this tendency for separate metal parts to wanna cling together.

Good stuff

When you milled the square portion, how did you reference the square faces to the round rotary spindle portion? Is it just relying on the setup of the square on the 4 jaw on the lathe?

Congratulations on 100k. Good job on the part too.

Thank you so much 😀

Makes me wince every time you put your finger on a moving part in the lathe. I worked with a guy that used to do that. Emphasis on 'used to'.

And your point is???

@@TopperMachineLLC He split his thumb open to the bone on a burr he didn't think was there.

Please get a tripod for your camera

Nice job. Lucky that 3/8 pilot didn’t snap looking at the hole. Makes you wonder if there was some slag rolled into the plate looking at where the oxy cut went 🤷♂️

Just run across your channel. Great content.Great repair!

Thanks and welcome

so stupid, wast a lot of times and material to turning it .

This comment is stupid. You have no idea the application, nor the time it actually took to do the job.

@TopperMachineLLC I work in a machinery company. If we need a part like this. We use near shap forged piece for high toughness elements. Or use disk and rod 100% welding for common elements.

I'm always amazed at how much replacement parts cost. I did some work for a shop that made replacement parts for diesel engines and the owner said "if you had to build a new engine with all genuine replacement parts you could pay off the national debt." I appreciate you sharing the prices of OEM parts and it shows how important what you do is to the small business man (aka farmer).

I watched my dad and neighbor working machines in a small shop through the window, he wouldn't let me in the shop. I've seen my dad get so stressed he would go outside kick the trash can and smoke a cigarette. Then went back to work! He didn't want me to be a machinist! Years later he pushed me to be a auto mechanic!

Happy days Josh, turned out lovely, hope you didn't feel too pressed 😂 cheers buddy, a shot well earned

Being able to make your own dry ice is nifty. Thanks for the video.

Nifty and essential to what I do here. Closest place to get dry ice is an hour drive away.

Typical Josh topper "get it right those time" always.

I'm glad I'm not the only one who always goes the wrong way first with coaxial indicator.

Big thing about using dry ice vs LN2 is -109 degree F vs -320 degree F, you only get about one-third of the shrink; gotta keep that in mind. With LN2, the part probably would have dropped right in (at the expense of 2 hours driving to get the stuff). Anyway, nice job there, it's always interesting to see how people approach a problem and get it done.

It would have been 2 hours of driving for dry ice, that is why I make it. LN2 would be 3-4 hours of drive time, making that unacceptable. I can't bill for time and materials to get supplies for a simple job. I wish I could get LN2, it just can't happen here, too depressed of a region.

I don't even like watching those press fits and I'm not even responsible for the outcome. Assuming it's one of those things that no matter how many you do, you're never really relaxed. Is there a formula or table you machinists use to know how how to size those? Or just learned from experience and hopefully as little trial and error as possible? I'd imagine the properties of the materials matter too for how much they expend and contract.

I am always nervous doing this work. Generally, 0.002" for each inch of diameter is the high end for a shrink fit. I went just a little more for safety.

What did you buy it for ? I got it and the hoe

I’m pretty sure that CNH actually stands for Can Not Have. Owned by parent company Fiat, which must be Italian for Fix It Again Tomorrow. I have been operating and maintaining a first generation New Holland large square baler for 25 years this year. It is appalling how many parts are no longer available (NLA in CNH speak). If they are available the price is obscene. FWIW -- CIH labeled pre New Holland/Case IH merger large square balers were built by Heston here in the US. After the merger, CIH large squares were rebadged New Holland machines. All large square balers built by New Holland except the New Holland 2000 were built in Zedelgem Belgium.

I have never done it that way and mabye that is because that has more wear than I have seen. I use a boring head (left hand boring bar faceing the inside of boring head) and machine it to a smaller diameter and make a sleeve to bring it back to spec.

Depends on the application. I have done both ways. Check out my video from the previous week.

Thank you Josh!

Nice to have that press nearby!

Always be prepared

Awesome crane. Love it. You are amazing, your skill set is so vast and varied! A X7 railroad crane operator!!!

congrats on the 100k, been here since like 5k if i remember correctly, thanks for the content, love the cool stuff like shrink fits and whatnot, cheers buddy

Awesome! Thank you! 👍

Just a note about sawing off the pin with a slitting saw, slitting saws are pricey but my favorite alternative nowadays is the 8 inch carbide tip blades they sell for metal cutting skilsaw type saws. They are cheap like 40 bucks and less kerf, I have one on an R8 arbor I use all the time for cutting down pieces too short to hold in the bandsaw, slotting, or even have used it in the angle head for cutting plate clamped down to the table. Works great and in 4 years now I am still on the first saw blade of the 2 pack I bought!

Nice. Great idea, I'll be using this.

As long as the beer dose not open till you are done. Once the beer comes out the wrenches stay put away in my shop.( unless it's my own shit.)

Yeah screw those people that just complain I don't see them doing precise machine work with repeat customers

Beautiful Job Josh.

Thank you!

Thanks for taking the time to post this, I always enjoy "repairs" ! Cheers

Thanks for watching!

Hey Josh, not a machinist but enjoy and respect your work!

Hey, thanks!

a beer never worked for me maybe a 12 pack

I think if you had cleaned both the bore and mating shaft with some fine grit or emory, it would have been a cleaner fit and no press would have been needed. What looks like a smooth finish to our imperfect eyes is really very rough under a scope. Keep up the great work Josh.

That new ENCO lathe is sweet!

Good one Josh . Plan B is always the press , preferably close by ! I like that boring head , although it is completely different to the D'Andrea i used to use . That had 3 speed feed & rapid return traverse . Cheers 👍

I'm having a hard time finding this thing. I know there was a unit just like it that I thought was D'Andrea. I could be wrong.

'Do it right the first time'. Trying, and will get there, eventually!?.

hi very important to do when you're pressing there is a book that gives you the exact diameters for a press fit slip fit based on diameter of the shaft. you can find one the Internet Next time you press shaft give yourself a small taper about taper so you know it's going in straight and put a heavy grease on the shaft and the bore.

I have all the specs, this was done to be extra tight so it would not losen up.

Try liquid nitrogen next time

If it were available here, I would. Dry ice is hard enough to get that I have to make it.

Do ever wash your pants?

Nope, do you?

Real good fix

Never did say what the parent metal was. It looked like steel to me and not cast Iron. The pin you turned was Steel but what grade? Inquiring minds need to know. Loved the video and the use of coaxial indicator. You logged the center position of the pin hole and then macked off the pin. I loved the results. .003 fit is tight. I noticed you did not skim the surface of the wheel the saw must have left a satisfactory finish. Hope the baler runs another fifty years. New Holland balers and swathers are around sitting out in fields rusting. My guess is pin was 1045. But I have been wrong before. Cheers.

My guess is that the piece was ductile iron. But that's just a guess.

Heard it pop when you jacked it in with the press I always grab a felt tip pen and put the date on the oxygen cylinder and the acetylene. Just so I know when I last exchanged them. Do you drive to town to get refills?@@TopperMachineLLC

@@martinnorbeck4657 I have 2 of each bottle that is frequently used so one can be taken in when it's convenient. I no longer use acetylene. I switched to propane and filled off my bulk tank.

That was a brown pants moment at the end. Glad it worked out.

Exactly

Saving perfectly serviceable machinery one part at a time. Try that with CNC. Writing the program alone would probably exceed what you charged. Want one or two parts use 'old time' shop machinery. Want a thousand parts use CNC.

Hope you enjoyed the beer, you sure deserve it.

I did!

i was drinking a beer while watching the video

I even needed a beer after that pin stuck! glad the press was handy and it worked!